Adequate sourcing strategy is a vital element for any successful organization.

Product costing, supplier base, manufacturing process are key to determine the final product cost and ensure smooth supplies.

ALLIANCE Team can help you to execute the right sourcing strategy.

We act as a single-window supplier of components and assemblies to our customers taking responsibility for Quality, Cost & Delivery.

Our customers have benefited in various ways:-

We carry out pre-RFQ activities.

Right decisions at the RFQ stage – Quick product launch and reduced sourcing time and cost !

We source, procure and develop various components and assemblies – Machining, Castings (Ferrous and Non-Ferrous), Stampings, Forgings, Plastic Parts, Precision Machining parts, Pipe Bending and manipulation parts, Hardware, Fencing and many more...

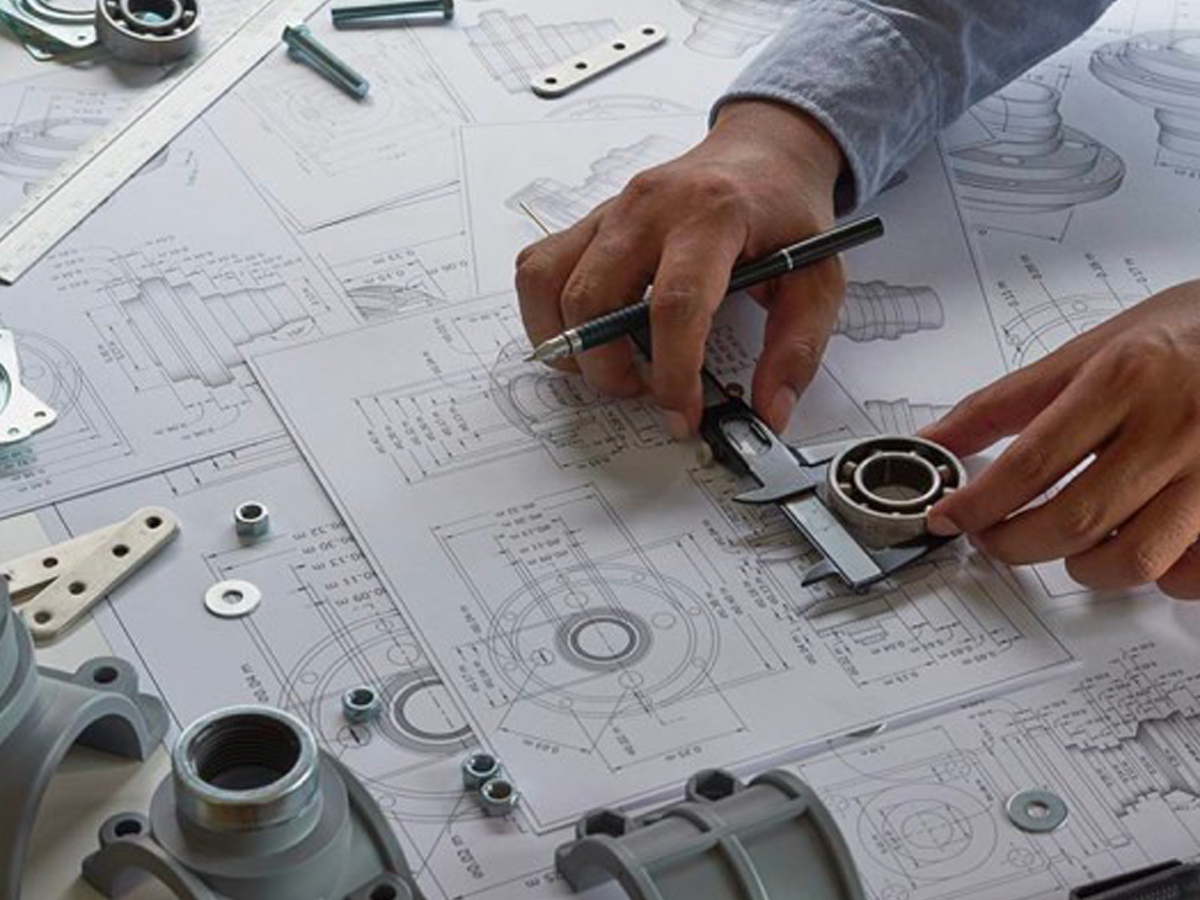

Our product development team is constantly looking for ways to improve your product's performance and make your design work for you. Our engineers review your project's parameters and make cost saving recommendations based on the most efficient design.

Our engineering team can help generate new and innovative concepts for your product, and having a variety of concepts to choose from ensures that your design suits you. Our engineers can take your current design and efficiently change the mode of manufacturing to develop a better and stronger product at a competitive price.

We would love to work with you or your engineers to help discuss the best options to help in the design and manufacturing of the new process.

ALLIANCE approach to quality control is designed to ensure optimal product quality, strict adherence to your design, and a reduced cost to you. From first article sample submission all the way through to full production, our QC staff is always on the lookout for ways to improve product quality. We are constantly addressing manufacturing processes, material concerns, and improving staff expertise to ensure the highest quality product.

We monitors our factories so you don't have to. We check quality control overseas and then double check when your product gets to dispatch.

ALLIANCE has relationships with hundreds of factories that can provide you with a custom manufacturing solution. Each factory on our approved vendor list is thoroughly ensure they meet the highest quality standards. Our experienced product development engineers can help develop your design and move it through the production process. Adhere to it, we may require.

Our engineers' extensive knowledge of the global and domestic manufacturing landscape allows us to ensure: